Servo Motors For Motion Control Application

Price 90000-2500000 INR/ Unit

Servo Motors For Motion Control Application Specification

- Speed Range

- 0-3000 rpm

- Remote Control

- Yes

- Features

- High Precision, Low Noise, Fast Response, Energy Efficient

- Application

- Motion Control Applications

- Frequency

- 50/60 Hz

- Processor Type

- Integrated Digital Signal Processor

- Weight

- 2.5 kg

- Sensor Type

- Incremental/Absolute Encoder

- Phase

- Single Phase/Three Phase

- Load Capacity

- Up to 10 Nm

- Mounting Type

- Flange/Foot Mount

- Connectivity Type

- Wired

- IP Rating

- IP65

- Control Type

- Closed Loop

- Drive Type

- Electric

- Automation Grade

- Automatic

- Cable Length

- 3 Meters

- Material

- Aluminum Alloy Housing

- Power

- 750 W

- Temperature

- -20C to +60C

- Voltage

- 220V AC

- Torque Range

- 0.3 to 10 Nm

- Cooling Type

- Natural Air Cooled

- Motor Feedback

- Resolver/Encoder

- Insulation Class

- Class F

- Peak Current

- Up to 4.5A

- Construction

- Brushless DC (BLDC) Motor

- Enclosure

- Totally Enclosed

- Shaft Diameter

- 14 mm

- Color

- Grey-Silver

- Gear Type

- Optional Planetary Gearbox

- Noise Level

- <65 dB

- Duty Cycle

- Continuous (S1)

Servo Motors For Motion Control Application Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Day

- Delivery Time

- 1 Week

- Sample Policy

- Within a certain price range free samples are available

About Servo Motors For Motion Control Application

KEB Servo Motors

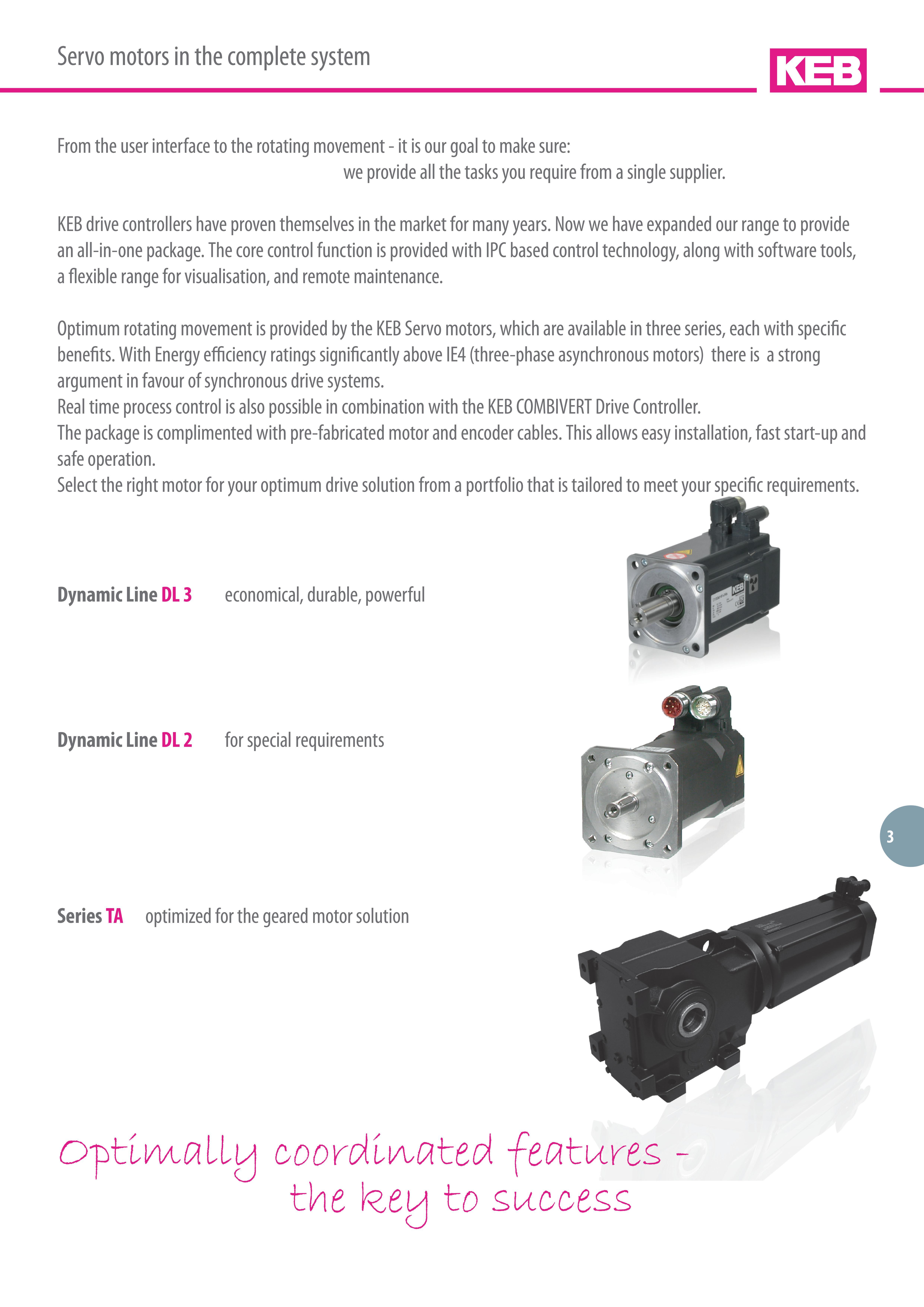

From the user interface to the rotating movement - it is our goal to make sure: we provide all the tasks you require from a single supplier. KEB drive controllers have proven themselves in the market for many years. Now we have expanded our range to provide an all-in-one package. The core control function is provided with IPC based control technology, along with software tools, a exible range for visualisation, and remote maintenance. Optimum rotating movement is provided by the KEB Servo motors, which are available in three series, each with specifc benefts. With Energy efciency ratings signifcantly above IE4 (three-phase asynchronous motors) there is a strong argument in favour of synchronous drive systems. Real time process control is also possible in combination with the KEB COMBIVERT Drive Controller. The package is complimented with pre-fabricated motor and encoder cables. This allows easy installation, fast start-up and safe operation. Select the right motor for your optimum drive solution from a portfolio that is tailored to meet your specifc requirements

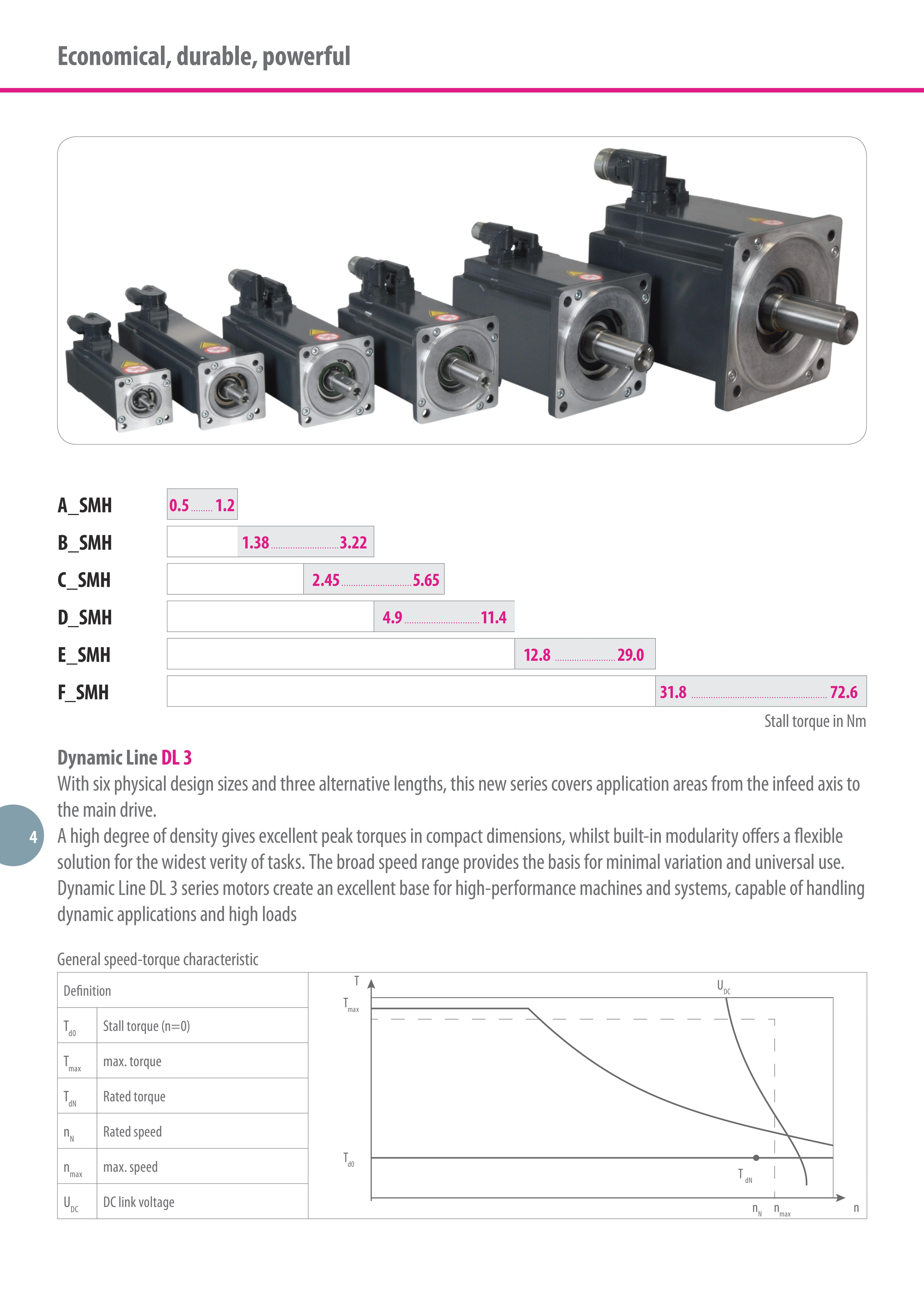

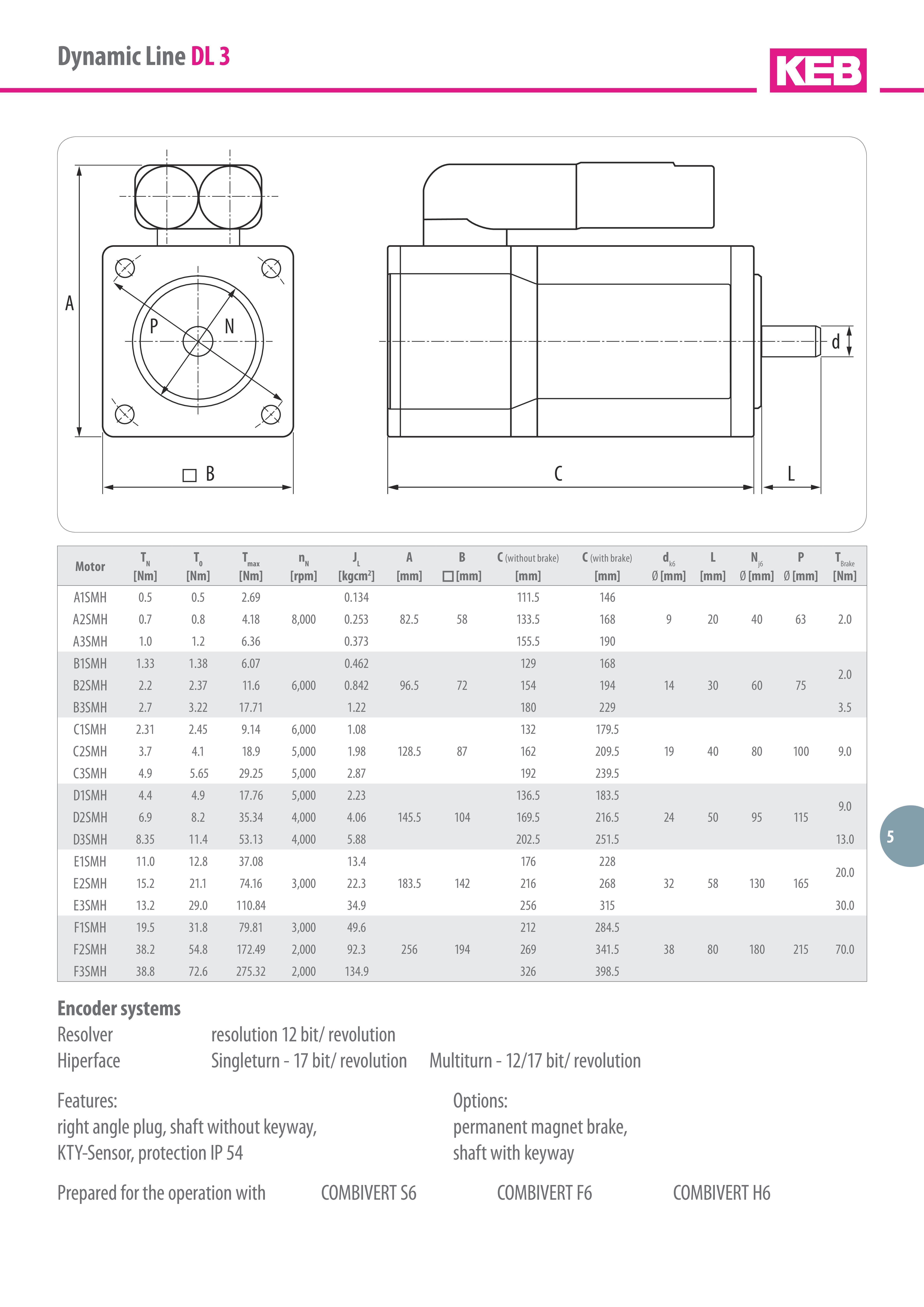

Dynamic Line DL 3

With six physical design sizes and three alternative lengths, this new series covers application areas from the infeed axis to the main drive. A high degree of density gives excellent peak torques in compact dimensions, whilst built-in modularity oers a exible solution for the widest verity of tasks. The broad speed range provides the basis for minimal variation and universal use. Dynamic Line DL 3 series motors create an excellent base for high-performance machines and systems, capable of handling dynamic applications and high loads

Dynamic Line DL 2

This series oers the latest motor technology in fve physical design sizes.They have been confgured for tasks with a high system resolution, short designs and small build volumes, and are particularly suitable for difcult mechanical conditions such as vibration, installation, location or temperature. With pre-fabricated cables and an electronic name plate (BISS) the start-up process and potential for error during installation is minimized. The result is a high degree of availability and maximum serviceability.

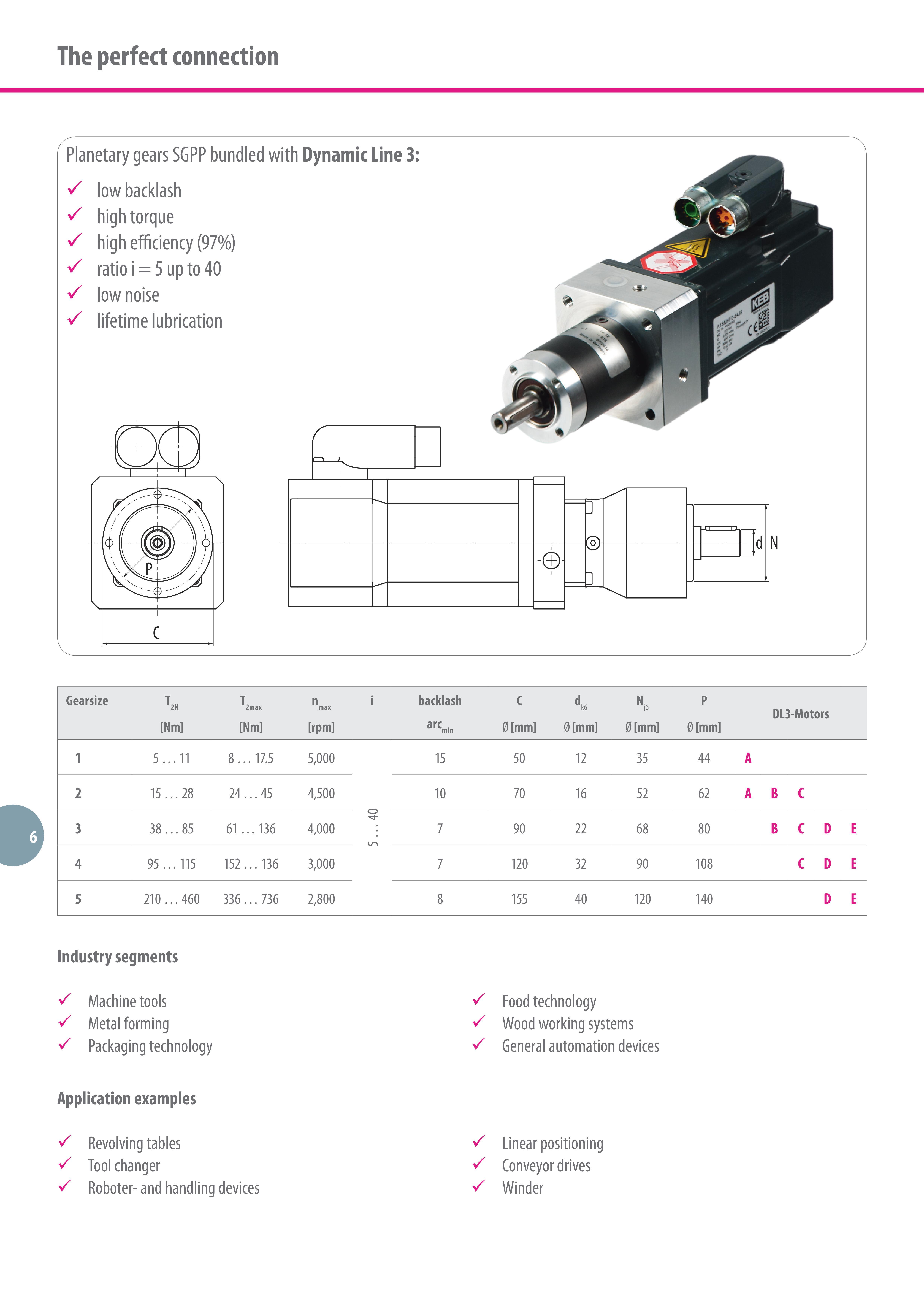

Ta Series Servo technology in combination with an industrial gear box module gives rise to a variety of servo geared motor types: spur, shaft-mounted helical, helical worm, helical bevel and planetary gear. The direct input into the gearhead reduces the work that would otherwise be required with a conventional connection coupler, increasing efciency and service life in a particularly compact design. As a exible solution from the gearhead module, the servo gear motor oers high overall efciency and excellent dynamics, as well as reduced backlash option (on request). The TA Range oers properties such as lifetime lubrication, universal installation positions and robust mechanics.

KEB DRIVE is our perfect software tool for geared motor selections, based on a combination of continuous torque and peak current dependent on the nominal torque. It also provides technical data sheets, 2D and 3D engineering fles as well as the ability to allocate a matching controller.

Product details

| Voltage | 415 |

| Usage/Application | AUTOMATION |

| Type | AC |

| Power | 1 TO 100 NM |

| Phase | 3 |

| Speed | 3000 |

| Input Phase | 3 |

| Torque | 1 TO 100 NM |

| Model Name/Number | 1S |

High-Precision Motion Control

Our servo motors offer accurate speed and positioning thanks to integrated digital signal processing and encoder feedback. This leads to reliable, repeatable results, which are vital for advanced automation and motion control setups.

Flexible Duty and Mounting Options

With continuous duty (S1) design, options for flange or foot mounting, and a 3-meter cable length, these motors fit seamlessly into various industrial configurations. They are compatible with three-phase and single-phase systems.

Durable and Efficient Construction

Constructed using aluminum alloy housing and sealed to an IP65 rating, these motors resist challenging environmental conditions. Natural air cooling and energy-efficient operation ensure long-term performance.

FAQs of Servo Motors For Motion Control Application:

Q: How are servo motors with Class F insulation suitable for continuous motion control applications?

A: Class F insulation allows the servo motors to handle higher operating temperatures up to 155C, making them ideal for continuous-duty (S1) cycles in demanding motion control environments without thermal degradation.Q: What is the benefit of using an optional planetary gearbox in these servo motors?

A: Including a planetary gearbox enables higher torque transmission while maintaining compact size and efficient operation, supporting demanding automation tasks that require increased load capacity up to 10 Nm.Q: Where can these servo motors be installed given their IP65 enclosure rating?

A: These motors can be installed in environments exposed to dust and water projection, such as manufacturing floors or industrial automation settings, without risk of damage due to their totally enclosed, IP65-rated design.Q: What processes do the resolver and encoder feedback enable in motion control?

A: Resolver or encoder feedback provides precise position and speed data for closed-loop control, ensuring accurate, repeatable movements and smooth operation in complex automation and robotic processes.Q: When is natural air cooling sufficient for servo motor operation?

A: Natural air cooling is effective within the temperature range of -20C to +60C and for applications where the peak current does not exceed 4.5A, helping to maintain motor performance without additional cooling systems.Q: How does remote control and integrated digital signal processor enhance usage?

A: Remote control facilitates flexible system management from a distance, while the integrated digital signal processor ensures fast response and high-precision control for complex automation tasks.Q: What are the main benefits of using these servo motors in motion control applications?

A: Key benefits include high precision, low noise operation, energy efficiency, fast response times, and the flexibility of closed-loop control, making them suitable for varied industrial automation solutions requiring reliable and efficient performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Automation Category

Servo Drives For Textile Industry Application

Price 90000-2500000 INR / Unit

Minimum Order Quantity : 1 Unit

Control Type : Digital Servo Control

Mounting Type : Panel/Wall Mounted

Load Capacity : Up to 500 kg

IP Rating : IP54

Servo Drives Motor Along With Pump

Price 90000-2500000 INR / Unit

Minimum Order Quantity : 1 Unit

Control Type : Servobased digital control

Mounting Type : Flange / Foot mounted

Load Capacity : up to 500 kg

IP Rating : IP54

KEB Frequency Inverter Vertical

Price 90000-2500000 INR / Unit

Minimum Order Quantity : 1 Unit

Control Type : Vector Control, V/f Control

Mounting Type : Vertical Wall Mount

Load Capacity : Adjustable up to 315 kW

IP Rating : IP20 / IP55

Servo Drives And Motors

Price 90000-2500000 INR / Unit

Minimum Order Quantity : 1 Unit

Control Type : Digital

Mounting Type : Flange Mount

Load Capacity : Up to 20 Nm (Torque)

IP Rating : IP20

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free